Fives, référence française de la tuyauterie industrielle et du nucléaire

Avec 120 années d’expérience auprès des plus grands noms de l’industrie, Fives Nordon est aujourd’hui une référence dans la conception et la réalisation d'équipements et de réseaux de tuyauterie à haute technicité.

Intégré aux marchés de l’énergie thermique et nucléaire depuis plus d’un demi-siècle, Fives Nordon a su gagner la confiance de clients prestigieux. Proximité, modernité, expertise multisectorielle : voilà ce qui fait l’ADN de l’entreprise aujourd’hui.

En 2024, Fives Nordon célèbre ses 120 ans !

120 ans d'histoire riche de progrès, de défis industriels, de haute technicité, d’innovation, de passion et d’excellence.

Un engagement envers l’excellence, la qualité, la sécurité, la sureté et l’innovation qui a façonné son histoire et continue de la propulser vers un avenir vertueux, durable et audacieux.

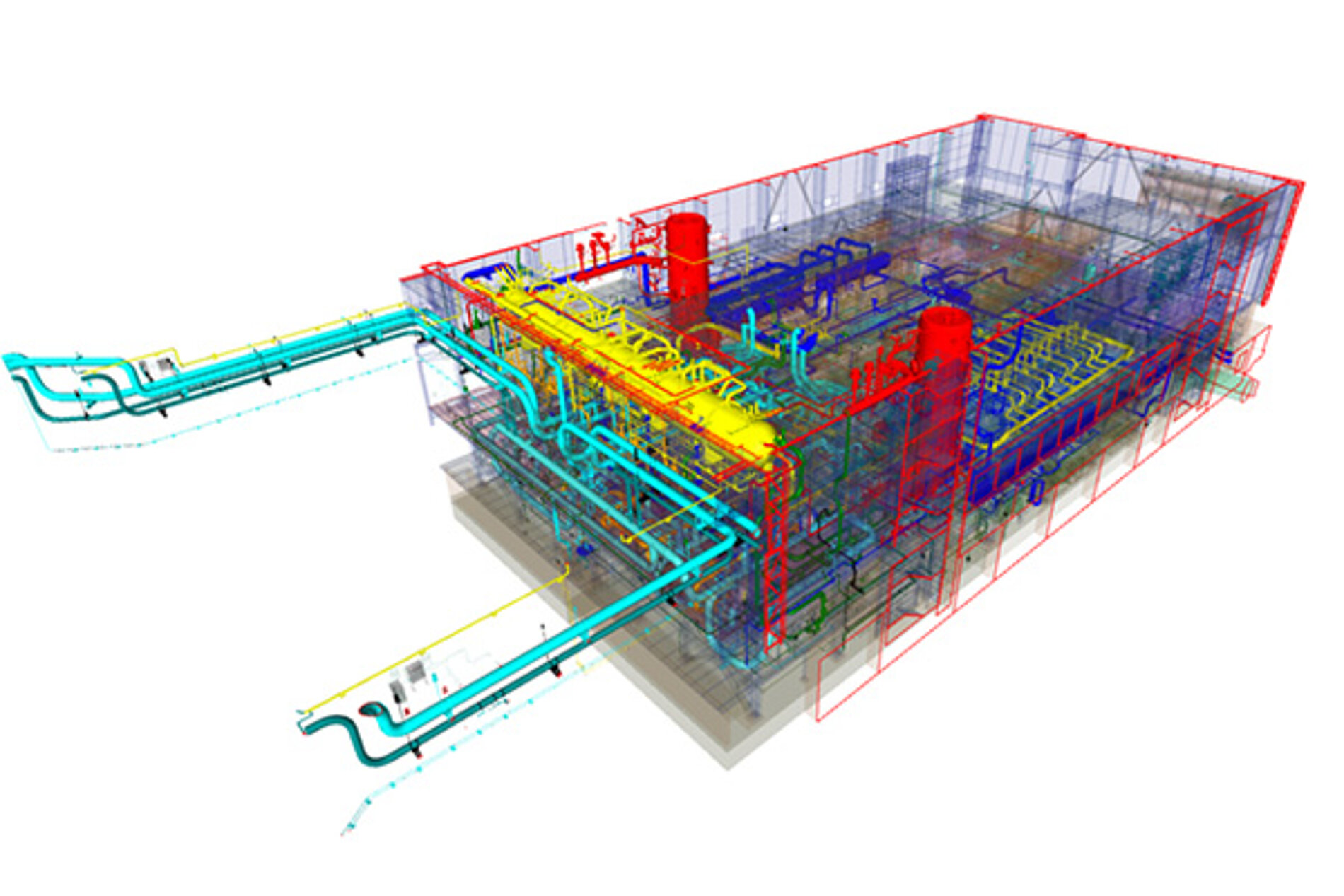

Conseil en ingénierie

L’expertise du bureau d’études et des techniciens Fives est à votre portée.

Tuyauterie neuve et projets en EPC

Faites appel à Fives pour le montage de vos installations et de vos équipements.

Maintenance et fiabilité

Profitez de notre expérience en maintenance pour tous vos projets industriels.

Des moyens de fabrication performants

Fives dispose notamment d’ateliers de tuyauterie dédiés au carbone, à l’aluminium et à l’inox.

Fives Nordon recrute 300 nouveaux talents d'ici 2025

Envie de rejoindre une grande famille présente partout en France ?

Fives Nordon est à la recherche des talents d’aujourd’hui et de demain.

Formation : découvrez l’Académie Fives Nordon

Nos 50 formateurs-experts dispensent des modules de formation dans les domaines de la tuyauterie, de la métallurgie, du soudage, des essais non destructifs, des contrôles et de divers aspects réglementaires.

Actualités Piping Solutions

Fives Nordon est un des leaders français dans le domaine de la tuyauterie et de la chaudronnerie industrielles de haute technicité, notamment au service de la filière nucléaire.

La ministre a souhaité organiser cette visite de Fives Nordon à Nancy, spécialiste de la tuyauterie et chaudronnerie industrielles, pour rencontrer nos salariés et notamment nos alternants et échanger…

Cet évènement est l’occasion de partager sur nos actualités et enjeux en matière de formation et recrutement, particulièrement en lien avec les perspectives d’activité de la filière nucléaire en…